R&D collaborative projects

CLIMBIN, a collaborative R&D project, to meet the societal challenge of producing new biotherapies and novel production tools.

Winner of the Call “New biotherapies and production tools”, CLIMBIN project is funded by the French government for a total budget of €2.2 million

The development of biotherapies (recombinant proteins, antibodies, vaccines) and advanced therapy medicinal products (gene therapy drugs, somatic cell therapy drugs, drugs from cell or tissue engineering, combined innovative therapy drugs) is a real opportunity to better care for patients.

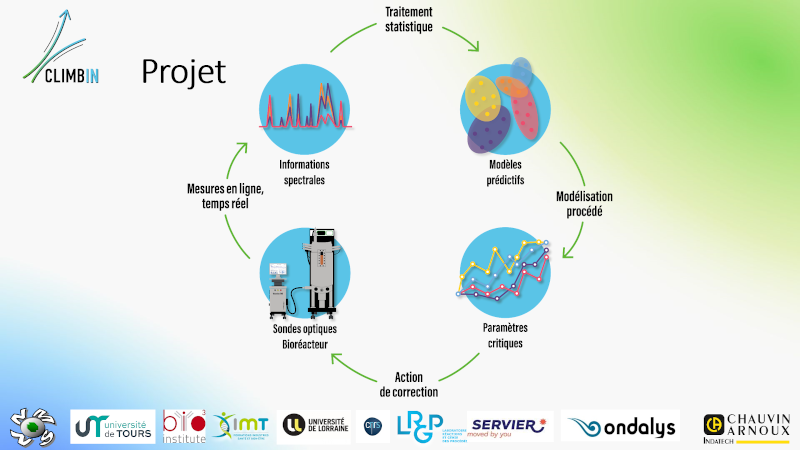

However, the production of these Advanced Therapy Medicines (ATMs) is still very expensive. Thus, the CLIMBIN project aimed to develop an innovative analytical process control solution that addresses the optimization and automation problems of cell culture systems, in USP (upstream process) and DSP (downstream process).

This solution allows pharmaceutical and biotechs firms as well as CDMO (Contract Development and Manufacturing Organization) to reduce their production times and costs and thus make therapeutic products accessible to as many patients as possible.

With CLIMBIN, the project partners will make available to the biomanufacturing sector an innovative solution based on optimized in-line Raman spectroscopy Process Analytical Technology by Molecular Optical Spectrometry. This solution, applying the Process Analytical Technology approach (PAT), is ready to use and suitable for suspension cultures (CHO) in various types of bioreactors.

By monitoring critical process and quality parameters in real time, disruptive advantages are expected in terms of control, industrial performance and CSR (Corporate Social Responsibility).

> Objective : Improving the productivity of mammalian cell cultures (CHO) and monoclonal antibodies (mAbs)

The global objective of the project was to design a system to better monitor cell cultures. The idea was to use innovative and optimized optical sensors (spectrometers) providing in-situ and real-time measurements and to predict Critical Process Parameters (CCPs) and Critical Quality Attributes (CQAs) using Machine Learning (ML) algorithms.

> Cell culture batches in an industrial environment

Several batches of cell cultures were carried out in the 3 laboratories of the consortium, in an up-scaling way, i.e. at LRGP, NMNS and in Servier Laboratories.

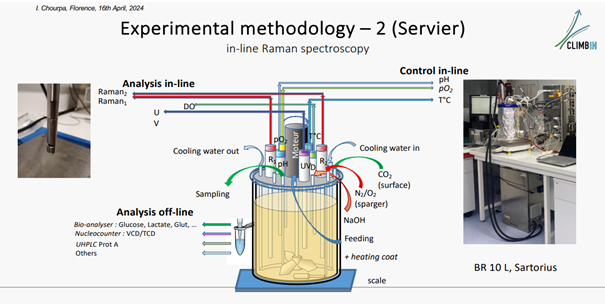

During this scale-up, the bioreactors were always instrumented in order to measure in-situ Critical Process Parameters (CPPs) such as temperature, pH, oxygen pressure, etc.

Moreover, in-situ Raman probes made it possible to measure spectra in real-time. Those spectra are used to predict CPPS as well as Critical Quality Attributes (CQAs) such as nutrients (e.g. glucose, glutamine), metabolites (e.g. lactate, glutamate) and other criteria such as antibody concentration (Titer), Total Cell Density (TCD) or Viable Cell Density (VCD).

For all batches produced in the project, those parameters were also measured offline, in order to constitute a reliable database for spectrometer calibration purposes.

> Optimization of Raman measurement solutions

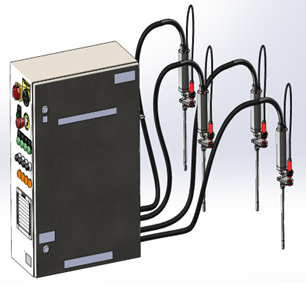

The Raman spectrometer (Viserion®) of INDATECH-Chauvin Arnoux Group can perform real-time measurements in 4 bioreactors simultaneously using 4 in-situ probes and with different excitation laser wavelengths.

During the project, the measurement system was innovatively optimized in order to improve performances in terms of sensitivity, signal-to-noise, robustness regarding to stray light as well as the increasing turbidity of the measured media during cell culture.

> Using Machine Learning for the prediction of CPPs and CQAs

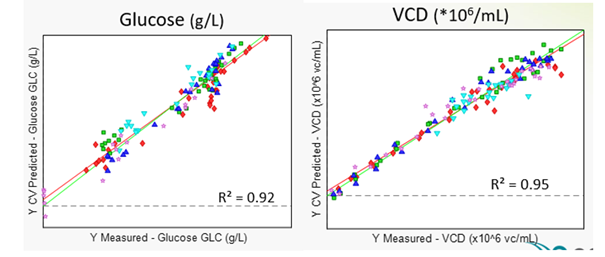

The measurements acquired in the bioreactors with the Raman probes were analyzed using Machine Learning algorithms in order to predict in real time the Critical Process Parameters (CPPs) and Critical Quality Attributes (CQAs) such as glucose, lactate, antibody concentration (Titer), Total Cell Density (TCD) or Viable Cell Density (VCD).

Those PAT tools have proven their performance for monitoring the fed-batch processes of mammalian cell culture for mAbs production.

> A consortium of complementary partners

This collaborative Research and Development project brought together the following French partners:

- the NMNS laboratory – NanoMedicines and NanoProbes – of the University of Tours, France – Professor Igor Chourpa and his team

The NMNS is the project coordinator and brings its skills on sensors, vibrational spectroscopy and data analysis. In partnership with Bio3, this laboratory of the University of Tours was able to characterize the optical spectroscopy equipment throughout their optimization during the 3 years of the project for the measurement of cell cultures.

- the LRGP laboratory – Laboratoire Réactions et Génie des Processus – of the University of Lorraine/CNRS, Nancy, France – Dr. Emmanuel Guedon and his team

The LRGP, expert for decades in process engineering on mammalian cell cultures (CHO), carried out cell cultures in small-volume bioreactors (Erlenmeyer flasks or mini-bioreactors) in order to characterize the innovative spectroscopic probes developed during the project.

- the pharmaceutical group Servier, Bio-S, Gidy, France – Sylvain Arnoux and his team

The pharmaceutical group Servier carried out cell cultures on its R&D, engineering and biomedicine production site at Bio-S in Gidy. These batches were carried out under industrial conditions in instrumented bioreactors, in order to monitor the Critical Quality Attributes (CQAs) and the Critical Process Parameters (CPPs) of cell cultures (CHO cells) for the mAbs production.

- INDATECH, Chauvin Arnoux Group, Montpellier, France – Dr. Fabien Chauchard and his team

The equipment manufacturer INDATECH designs and manufactures optical spectrometers (near-infrared, Raman, UV) for laboratory, inline and in-situ applications. During the project, the company optimized the spectroscopic equipments in order to make the systems more efficient for inline measurement in bioreactors.

- Ondalys Company, Montpellier, France – Dr. Sylvie Roussel and her team

Ondalys Company is an expert in data analysis of diverse data (spectroscopy, imaging, process parameters, OMICS) for the development of processes in biotechnology, in particular through the Quality-by-Design (QbD) and (Process Analytical Technology – PAT) approaches. The team developed the CPPs and CQAs prediction models based on the innovative spectroscopic sensors developed during the project by INDATECH Company.

This project was funded by the French government

as part of the Recovery Plan and the Future Investment Program

ACCESS, a collaborative R & D project, for the production of Advanced Therapy Medicinal Products at a lower cost.

Winner of the call for proposals “Bio-medicines: improving yields and controlling production costs”, ACCESS is a project worth more than €2.5 M.

As part of the French Call for Proposals “Biomedicine: improving yields and controlling production costs“, the ACCESS – (Advanced Cell Control by Spectroscopic Sensors) project, a collaborative R & D project, received a favorable opinion from BPI France to meet the societal challenge of producing advanced therapy medicinal products (ATMP) at lower costs.

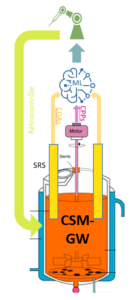

The ACCESS project aims to optimize Mesenchymal Stem Cell (MSC) cultures in bioreactors through online production control. This control will be based on innovative online optical sensors, Machine Learning algorithms and automated real-time feedback coupled with a digital twin and a Quality-by-Design (QbD) approach for process modeling.

This collaborative project led by INDATECH – groupe Chauvin Arnoux brings together MTInov integrator, Ondalys, Cybernano, Ypso Facto and StemInov.

This project will make it possible to structure French integrated QbD/PAT offer with European influence for the control of all types of adherent cell cultures in biotechnology. This will be organized thanks to suppliers of complementary products and services, ranging from process modeling (Ypso Facto, Cybernano) to the industrial implementation of online control (INDATECH, Ondalys, Cybernano).

This project was funded by the French government

as part of the Recovery Plan and the Future Investment Program

To know more about Ondalys’ expertise in process supervision for industry 4.0 .

Our training sessions

Ondalys proposes in-house training sessions for industrial and academic scientifics..

Our expertise to make sense of your data

With more than 20 years of experience in data analysis (Chemometrics), particularly applied to spectroscopic and process measurements, our team supports you at each stage of your projects.